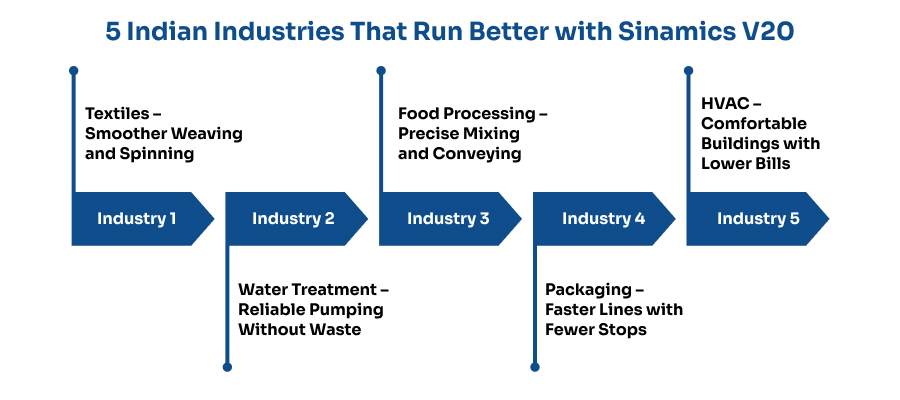

Indian factories buzz with motion but maintaining efficient motors can be a big challenge. Five industry verticals where the SINAMICs V20 excels are highlighted in this article. We will see how this compact drive reduces energy consumption, simplifies setup and improves reliability based on real-life examples from Siemens applications. A trusted supplier, Naksh Technology Solutions LLP helps industries integrate these tools and we will see why it matters.

Overview: Why SINAMICS V20 Fits Indian Industries

The SINAMICS V20 simplifies operation in energy hungry sectors with simple motor control and savings incorporated. Here’s a quick breakdown:

- Compact and Versatile: Handles between 0.12 kW and 30 kW, suitable for pumps, fans and conveyors in tight places.

- Quick Setup: Use connection macros for fast wiring and application macros for tailored tasks like mixing or ventilation.

- Energy Focus: In Siemens V20 energy saving functions optimize motor speed to reduce power draw in 24/7 runs.

- Easy Programming: Tweaks are easy with options like Programming SINAMICS V20 by interface, USB or via web/Smart Access.

- Proven in India: Powers textile looms, water pumps and food mixers with little downtime and low bills.

For a deeper dive into its role in energy efficiency, visit our blog post How SINAMICS V20 Helps Cut Energy Costs in Industrial Plants.

Frequency Converter Basics: The Foundation of SINAMICS V20

Motors in factories do not need to run at full speed all the time, but the traditional setups waste power when they run that way. A sinamics v20 ac drive changes this by being a smart middleman. This device takes in incoming power and adjusts frequency to control motor speed precisely. Slow it down for light loads and speed it up when needed. Think of it as a dimmer switch for industrial machines but much tougher.

In India, where electricity costs climb yearly, these are the basics that matter. In most configurations the SINAMICS V20 supports single phase 200-240V or three phase 380-480V inputs. Its nine frame sizes fit well into crowded panels. One small textile unit might use it to sync loom speeds to avoid the jerk of direct starts that chew through belts.

Engineers love that this SIEMENS product handles overloads of up to 150% for short bursts without tripping. And with coated circuit boards it’s dust free unlike what you find in Indian workshops. This reliability makes headaches disappear.

How SINAMICS V20 Powers Key Indian Industries

SINAMICS V20 is a compact and modular drive, which brings precise motor control and energy savings. This sinamics v20 ac drive meets sector needs from dusty textile mills to modern HVAC systems. Below, we describe its impact on five key industries and show how Siemens V20 energy saving functions and smart features drive performance across the board.

Industry 1: Textiles – Smoother Weaving and Spinning

Textile mills in hubs like Surat weave and spin continuously on tight margins. Uneven motor speeds or high power spikes disturb output and raise costs. And here comes the SINAMICS V20 with tailored control for quiet operation and low energy bills in these demanding applications.

- Adaptive Speed Control: Matches spindle and loom speeds to yarn tension; avoids breaks; maintains fabric quality over high-volume runs.

- Power Efficiency: Uses Siemens V20 energy saving functions to reduce consumption on idle machines such as dyeing pumps by dynamically scaling frequency.

- Fast Configuration: Programming SINAMICS V20 via interface, USB, or via web / Smart Access allows quick tweaks for multi-stage textile processes reducing setup time.

- Dust-Resistant Design: Dusty conditions and coated boards with IP20 enclosure extend motor life in spinning & weaving setups.

- Surge Handling: Handles up to 150% overload in short bursts, looms remain stable during sudden spikes in demand without tripping.

Industry 2: Water Treatment – Reliable Pumping Without Waste

Water treatment plants across India, from municipal facilities to industrial units, rely on pumps that are hungry for power. Variable flow demands and severe environmental conditions can break the systems. With the sinamics v20 inverter, optimal pumping with high efficiency and reliability is achieved to avoid waste water.

- Flow Optimization: Modifies pump speeds based on real time water demand, saving energy use in low flow periods of filtration or effluent systems.

- Stable Power Delivery: Clean voltage output frequency converter basics protect sensitive equipment from harmonic distortions in treatment setups.

- Remote Management: Web-based monitoring with SINAMICs V20 Smart Access module allows operators to make changes without site visits.

- Energy-Saving Modes: Activates eco-modes for derating power draw during off-peak cycles for reduced cost while also dropping the system pressure.

- Reliable Operation: Automatic restart after power dips, to permit 24/7 pumping, in environments which require this to manage humidity.

Industry 3: Food Processing – Precise Mixing and Conveying

India’s food processing sector from Punjab’s grain mills to dairy plants requires precision and hygiene. Mixers and conveyors need steady speeds to prevent batch inconsistencies. The SINAMICS V20 ensures quality output while controlling energy use.

- Consistent Torque: Offer vector control of the mixer and conveyer for stable mixing and conveying of viscous or delicate products without speed fluctuations.

- Gentle Startups: Uses soft ramps to reduce mechanical stress on gears in grinders or fillers, extending equipment life in clean production areas.

- Easy Parameter Cloning: Programming SINAMICS V20 via interface, USB or via web/Smart Access simplifies setup across multiple lines.

- Hygienic Build: Coated internals are resistant to moisture, meet food-grade standards and fit compactly in small space processing plants.

- Load Flexibility: Adjusts to different resistances in extruders or slicers, optimizing energy and preventing overloads during peak runs.

We’ve explained its role in improving flexibility in our post, How SINAMICS V20 Boosts Operational Flexibility in a Food Processing Plant.

Industry 4: Packaging – Faster Lines with Fewer Stops

Packaging lines moving in cities like Bangalore handle different products within tight deadlines. Variable loads and frequently stopped motors increase costs. The sinamics v20 ac drive ensures precision and speed while keeping lines without constant maintenance.

- Rapid Task Switching: Application macros allow quick filling, sealing or labeling setup for rapid product change on high-speed lines.

- Synchronized Motion: Tells conveyor and applicator speeds to decrease mistakes in handling cartons or bottles for steady packaging output.

- Power Recovery: Energy is captured during deceleration, reducing net consumption at continuous-run packing stations.

- Simple Diagnostics: Line stops are minimized with the SINAMICS V20 Smart access module with LED indicators and web Access for troubleshooting & quick Access.

- Space-Saving Design: Nine frame sizes permit tight panel mounting in modular packaging setups with little control room.

Industry 5: HVAC – Comfortable Buildings with Lower Bills

In India’s growing urban centers HVAC systems keep malls and offices cool but inefficient fans raise bills. The SINAMICS V20 tunes airflow to achieve occupant comfort with energy savings in large commercial buildings.

- Demand-Based Cooling: Matches fan/blower speeds to occupancy or to match set point, so as to avoid overcooling in low-traffic zones.

- Stable Voltage Handling: Withstands power fluctuations of +-20%, allowing operation in areas with unstable grids.

- Eco-Friendly Operation: Siemens V20 energy saving functions use sleep modes for idle zones & cut power for air handling units.

- Zoning Simplicity: Connection macros simplify wiring for variable air volume system (VAV) and accelerate installation in retrofits.

- Low-Noise Performance: Runs quietly with little vibration for occupant sensitive spaces and USB diagnostics for easy maintenance.

Why SINAMICS V20 Suits Indian Manufacturing

Across these sectors the SINAMICS V20 delivers with a power range from 0.12 kW for fans to 30 kW for pumps for small to medium setups. The vector mode does precise jobs like conveyor syncing and scalar mode does basic pumping. Large input tolerance of up to + -20% is maintained in power unstable areas.

Installation? Side-by-side mounting/plug-in operators make this an easy setup. Maintenance drops due to LED status and optional harmonic filters. Indian industries can cut costs on maintenance thanks to self-diagnostics through USB or web. V20 is not just a drive. It is a partner for growth.

We Boost Indian Industries with SINAMICS V20 at Naksh Technology

From syncing looms to optimizing pumps this sinamics v20 inverter solves daily challenges for factories to cut costs and increase output in a competitive environment. We at Naksh Technology Solutions LLP are working hard to bring these rugged drives to industries across India.

As a certified Siemens partner, we have the whole range in stock and can help with installs like those in local textile mills. Supported by ISO 9001 standards, our team delivers smooth setups that keep your operations running. From pharmaceuticals to renewables, we offer tailor made solutions. Contact us today and boost your success with SINAMICS V20.

FAQs Related to SINAMICS V20

Q.1. What are the power and voltage ratings of SINAMICS V20?

Ans. The SINAMICS V20 is available in a wide range of power ratings from 0.12 kW to 30 kW. It supports different voltage classes, including single-phase 230 V AC and three-phase 400 V AC supply systems, making it suitable for various small to medium-sized industrial applications.

Q.2. How to commission or configure SINAMICS V20?

Ans. Commissioning the SINAMICS V20 is simple and quick. It can be configured using:

- The integrated Basic Operator Panel (BOP) on the drive.

- The Optional Intelligent Operator Panel (IOP) for more advanced settings.

- PC-based tools such as SINAMICS V-Assistant software.

Users can easily set parameters, adjust speed, and monitor performance without requiring complex programming.

Q.3. What are connection macros and application macros in SINAMICS V20?

Ans. Connection Macros: Predefined settings that simplify wiring and ensure correct I/O signal configuration for standard applications.

Application Macros: Ready-made parameter sets designed for common applications like pumps, fans, and conveyors. They help in quick setup by automatically optimizing drive behavior for specific tasks.