Machine builders and plant engineers look for a small inverter to handle steady duty loads without causing cabinet layout problems. Here, the G120C drive fits perfectly with its reliable motor control, simple wiring, adaptable commissioning routines, and scalable communication options. This guide brings together specifications, wiring practices, commissioning workflows, and practical purchasing considerations to help you determine if SINAMICS G120C is right for your application. Discover also the fundamentals of frequency converters and useful cross-references to tools such as the SINAMICS V20 Smart Access module for teams working across Siemens drive families.

Overview: Key Facts About SINAMICS G120C

- Designed for OEMs/industrial users who require compact, cabinet-mounted converters.

- G120C can perform asynchronous motor control over several frame sizes.

- Straightforward wiring with labelled terminals for power, control, and safety circuits.

- Commissioning via TIA Portal or basic operator panels ensures a predictable setup.

- High-quality fieldbus connectivity with options for integrated automation networks.

- Load behaviour, frame size & after-sales support are common buying decisions.

Understanding the Role of a Frequency Converter

Modern plants require variable-speed control based on the fundamentals of frequency converters. A converter changes a fixed AC supply to a variable voltage and frequency, allowing motors to run at the speed required by the process rather than at full speed at all times. This reduces stress on mechanical systems, increases process accuracy, and minimizes excessive energy use in light-duty operation.

The SINAMICS G120C follows this principle with a compact architecture that fits snugly in tight spaces within control panels. Its design allows for reliable torque delivery over a wide speed range and is suitable for conveyor zones, mixers, packaging machines, and HVAC-driven circulation tasks. Engineers seeking optimised performance across multiple motion axes without adding complexity usually find the G120C’s profile ticks all the boxes.

For a closer look at energy-efficient drive technology, check out our article on the SINAMICS G120C and its role in optimizing industrial energy usage.

Technical Profile: What the SINAMICS G120C Offers

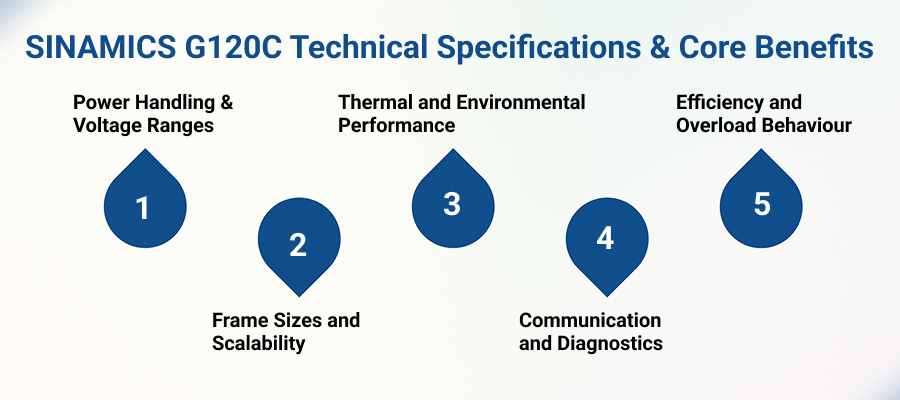

The performance parameters define the place of the SINAMICS G120C in an automation project. Avoiding rigid FAQ descriptions, the following sections outline practical specifications that engineers consider in real projects.

- Power Handling & Voltage Ranges

The converter is compatible with 200-240 V and 380-480 V supply systems for various industrial environments. This flexibility lets a single drive family support multiple machine types in the same plant. - Frame Sizes and Scalability

The G120C is available in several frame sizes, each built for a specific kW range. Compact frames for power tools and larger frames for conveyor or process equipment allow designers to standardize on a single series without oversizing. - Thermal and Environmental Performance

This hardware is capable of operating in typical factory conditions under stable thermal behaviour within its rated temperature window. Efficient IGBT structures reduce internal heat generation, supporting long runtimes inside crowded control cabinets. - Communication and Diagnostics

Automation teams appreciate communication choices. Integration into PROFINET-based cells or serial-based networks is straightforward, allowing for fast diagnostics, real-time control feedback, and system-wide fault tracing. - Efficiency and Overload Behaviour

The highlight of the G12C Drive family is its efficiency curve. High use at partial load and reliable overload capacity make it suitable for start-stop processes where torque peaks are important.

Wiring Practices for Reliable Operation

Good wiring is as important as picking the right drive. Predictable terminal layouts and clear labelling aid panel builders in reducing commissioning delays.

- Power Connection Principles: Inputs and outputs have standard terminal grouping for three-phase systems. Correct fusing and grounding ensure safety and electromagnetic stability. Electrical noise is reduced when shielded motor cables are used, especially for long runs.

- Control Terminals and Application Macros: Control wiring uses predefined configuration structures. The terminal sets include digital commands, analog references, and safety signals. Application-oriented macros map standard motor functions in minutes to keep projects moving in tight timelines.

- Switchgear and Protection Coordination: Adding reactors or EMC filters when the installation requires harmonic mitigation or improved immunity is common. These additions protect the drive as well as nearby automation hardware & instrumentation. Good wiring, combined with the correct accessories, provides a solid base for higher-level commissioning and plant reliability.

Commissioning Workflow: Getting the G120C Ready for Operation

Setting the scene for motion is called commissioning. The SINAMICS G120C facilitates this by supporting multiple configuration paths.

- Basic Parameter Entry: Operator panels enable the quick input of motor nameplate data as well as other parameters when engineers are working near the panel. This method is effective for small machines or single-axis installs.

- Commissioning via TIA Portal: Large automation cells normally use TIA Portal for uniform commissioning. Engineers connect over Ethernet or USB, build/import device profiles, parameter sets, and test the system in a step-by-step manner. That makes multi-drive projects uniform & easy to document.

- Comparing V20 Commissioning Tools: For teams with experience with the V20 line, workflows such as Programming SINAMICS V20 via interface, USB, web, and Smart Access provide a reference point. For lighter applications, the SINAMICS V20 Smart Access module provides wireless configuration, providing useful contrast when structuring programming tasks across machine families. The V20 is simple; the G120C adds diagnostics and greater automation flexibility.

Application Fit: Where the G120C Works Best

Industrial applications require drives that perform consistently across a wide range of tasks. This SINAMICS G120C works well in:

- Packaging Machinery: Smooth speed transitions and constant torque for fillers, labellers, pouch machines & wrapping systems.

- Conveyor Systems: Handles variable load behaviour over multi-zone conveyors with good acceleration and braking performance.

- Material-Handling Equipment: Supports hoists, sorters, and transfer units with predictable torque curves and good communication with PLCs.

- Food & Beverage Production: Assists in controlled movement of mixers, bottle conveyors, and precision dosing equipment where timing accuracy is critical.

- Light Manufacturing Lines: Fits small cabinets in assembly stations, machining areas & automated workcells where speed control is required.

- Textile and Printing Systems: Produces uniform motor performance for winding, unwinding, and tension-critical zones.

- HVAC and Utility Systems: Manage fan coils, blowers, and circulation motors using optimised energy use.

Buying Guidance: Making an Informed Decision

- Assess Load Behaviour First

Start with measured loads. Find typical and peak torque, speed ranges, and duty cycles. The selected G120C frame should match these conditions without overdriving the drive too far. - See Accessories for Power Quality

Line reactors, braking resistors, and EMC components ensure a smooth operation and protect sensitive equipment. Planning these additions early prevents delays when the machine reaches the site. - Evaluate Communication Requirements

Machine builders using PLC-driven networks choose G120C variants that support advanced fieldbus requirements. This allows future expansion and lowers the cost of adding interface modules. - Choose Authorised Partners

Hardware traceability, firmware updates & commissioning support are provided through official Siemens partners during procurement. For specialised businesses, the after-sales service should be as important as the drive.

How Naksh Technology Supports Your Automation Goals

The SINAMICS G120C strikes a balance between efficiency, scalability, and ease of use in various industrial applications. Its wiring structure allows clean installations, commissioning tools enable teams to deploy drives quickly, and communication meets modern automation requirements. Whether you run packaging lines, material handling systems, or process equipment, the drives’ performance characteristics ensure a solid foundation for consistent production.

In industries that require reliable motor control for day-to-day operations, we at Naksh Technology Solutions LLP work closely with such industries. As an authorized Siemens partner, our team supports you in selecting, integrating, and commissioning the SINAMICS G120C in compliance with load conditions and plant standards. If you’re planning an upgrade or a new project, we can help you select the right configuration, provide genuine hardware, and support your commissioning timelines. Contact our Siemens experts today to discuss your requirements or request a customised recommendation.

FAQs Related to SINAMICS G120C

Q. What communication interfaces does SINAMICS G120C support?

Ans: The G120C supports modern and legacy industrial communication protocols, making it highly versatile. Supported interfaces include:

- PROFINET

- PROFIBUS DP

- USS protocol

- Modbus RTU

- CANopen (optional)

This ensures seamless integration with Siemens PLCs and other brand PLCs.

Q. What power and voltage ranges are available?

Ans: SINAMICS G120C is available from around 0.55 kW to 132 kW across different variants. It supports 200–240V and 380–480V input ranges for flexible application use.

Q. What communication interfaces does it support?

Ans: The drive supports PROFINET, PROFIBUS, USS, Modbus RTU, and optional CANopen. This ensures easy integration with Siemens and non-Siemens PLC systems.

Q. How do you commission SINAMICS G120C?

Ans: Commissioning is done through STARTER or Startdrive software using guided setup wizards. You configure motor data, control mode, limits, and test motor rotation.

Q. How does SINAMICS G120C improve energy efficiency?

Ans. It uses ECO mode, automatic flux reduction, and optimized control algorithms to reduce power consumption. Industries commonly achieve 10–30% energy savings using this drive.