SINAMICS G120C is a compact inverter (variable frequency drive or VFD) for industrial use. It is intended for energy-efficient motor control for various machines like pumps, fans, conveyors, and mixers. Through its ability to precisely adjust motor speed according to the process demands, this VFD avoids its consumers’ energy wastes and throughput loss. This guide will look at the features of the G120C that provide industrial systems with energy efficiency and discuss why it is a good choice for OEMs and plant engineers in their attempts to reduce costs and radio emissions.

Technical Overview of SINAMICS G120C

The G120C is a frequency converter designed for single-motor low voltage, part of the SINAMICS family. The power ranges from 0.55 kW up to 132 kW (0.75–150 hp), with a standard supply voltage of three-phase 380–480 V. Most important technical features are:

- Control Modes: It provides for standard V/f control and vector control which is sensor less and high-performance (SLVC). Therefore, it can provide steady torque and accurate speed control without an encoder.

- Safety: Its built-in Safe Torque Off (STO) inhibits motor torque under specified conditions, therefore eliminating the need for an external contactor on emergency stops; high-availability options (PROFIsafe) are supported on bigger frame sizes.

- Communications: Provides connectivity with several fieldbus interfaces. G120C converters support PROFINET, EtherNet/IP, PROFIBUS DP, CANopen, and USS/Modbus RTU, which helps them integrate into various automation networks.

- Physical Design: The compact design of the G120C frames lends it a very high power density. An EMC filter and braking chopper can be fitted into the drive to make installation simpler. Units can be installed side-by-side on a backplate without derating, saving panel space.

In short, the G120C with its built-in capabilities is quickly wired into a control cabinet and commissioned with very few external components. The drive is a fully integrated member of the Siemens SINAMICS family, sharing TIA Portal configuration tools for easiest setup.

Key Features of Siemens SINAMICS G120C Drive

- Compact Footprint: Seven frame sizes cover the full 0.55–132 kW range. Though under a higher rating, the converter does not become large. Side-by-side mounting up to 132 kW is supported, which saves the trouble of the cabinet design.

- Energy-Efficient Vector Control: It uses encoder less vector control to produce high torque at low speeds. This maximizes motor performance with minimum losses.

- Automatic Flux Reduction (V/f ECO): This energy-saver “ECO” automatically reduces the magnetic flux of the motor at light loads, reducing the electricity used in light-duty cycles.

- Integrated Safety: Basic safety functions are an integral part of the drive: STO comes as standard and advanced safe motion profiles (PROFIsafe) for bigger units translate to fewer external safety hardware and ensures prompt safety-related motor shutdown when required.

- Smart Monitoring: Alongside energy consumption monitoring, the internal energy calculator logs power consumption. In addition to this, the energy calculator complies with the PROFIenergy profile and can therefore initiate automated idle/sleep states in coordinated systems. Consequently, operators can have full control and management over energy consumption directly from the drive.

- Flexible Commissioning: USB port and operator panels (BOP-2 / IOP-2) allow for intuitive configuration. Parameters are cloned via SD card or USB for fast multi-drive installation. The drive also supports the Siemens Smart Access Module, an optional wireless interface, for commissioning on the go.

- Rugged Construction: Rated for up to 60 °C ambient temperature, with derating. All electronics are coated for harsh environments. Meeting standard approvals (CE, UL) for worldwide OEM use.

The Energy-Saving Characteristics of the SINAMICS G120C Drive

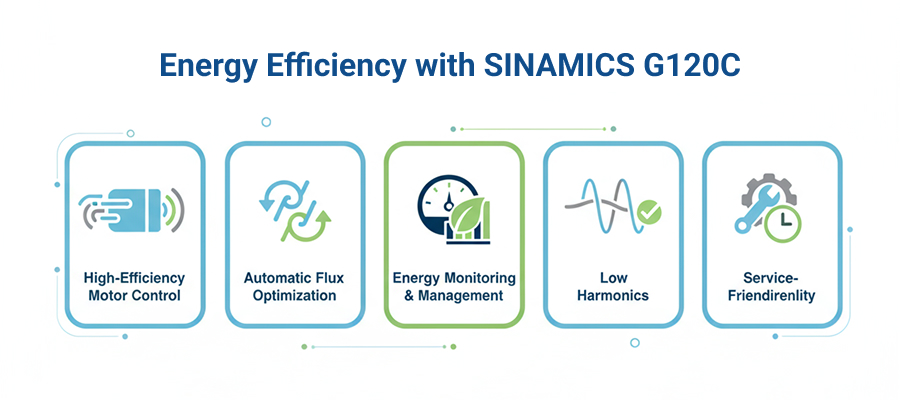

The SINAMICS G120C is particularly designed to conserve energy in industrial motor applications. These are the energy-saving features:

- High-Efficiency Motor Control: The G120C uses energy-efficient encoder less vector control to keep the torque/speed optimum with minimum losses. Vector control keeps motor flux and currents closer to ideal levels as compared to simple V/f control.

- Automatic Flux Optimization: The V/f ECO function attenuates motor flux at low loads so as to reduce no-load and magnetizing losses in case full torque is not required. This means that for example, for a pump operating well below capacity, power consumed will be much lower with this mode on.

- Energy Monitoring and Management: An integrated energy calculator keeps a kWh consumption record in the drive. With support from PROFIenergy, plants can put save-state-down-times (like sleep modes) into schedule. Besides, higher-level coordination brings down further energy consumption.

- Low Harmonics: Sophisticated internal filter design satisfies strict EMC standards. With such low harmonics, power is used cleanly with lesser heat dissipation in supply networks.

- Service-Friendliness: Well-engineered to minimize cooling requirement and oversize’s avoidance. Quick maintenance (i.e. plug-in terminals, easy diagnostics) helps in reducing downtime which translates to a more consistent efficiency of the equipment during its lifetime.

When these attributes are combined, manufacturers gain some neat, measurable energy savings. According to Siemens, a variable speed for a fan or pump conversion to SINAMICS drive usually offers an energy saving of 30 to 50 percent in different load profiles. Another brochure said that SINAMICS drives, including the G120C, have been able to achieve “up to 60%” energy savings in special situations. Even small percentage savings are huge if this is an industrial concern.

How Industries Benefit from the SINAMICS G120C Drive

The versatile SINAMICS G120C fits a multitude of industrial applications. Typical projects include:

- Pump and Ventilation: Water/wastewater treatment plants and irrigation pumping for HVAC. The G120C controls flow with precision while reducing pump power draw.

- Fans and Blowers: Adjusting speed control of fans in buildings and processing plants results in huge energy reductions (based on fan laws). G120C high-torque control allows smooth modulation of airflow.

- Compressors and Refrigeration: Operating chillers or compressed air systems, the drive sets motor speed to demand to gain efficiency over fixed-speed operation.

- Material Handling: Conveyors, cranes, and hoists require smooth acceleration and deceleration. G120C with built-in motor brake and STO yields efficiency and safety for lift and transport equipment.

- Machining and Process Equipment: Mixers, extruders, milling machines, and other OEM equipment utilize the drive for very precise speed/torque control. The small size is suitable for distributed drives mounted on machine frames.

In all applications, energy-saving features of the G120C (such as vector control, ECO mode, etc.) translate directly into savings on electricity bills. For instance, simply lowering the speed of a variable-torque load, such as a centrifugal pump or a fan, from 100% to 80% drastically reduces power consumption due to cubic power versus speed characteristics; the G120C technology aids in automating this process. The design built rugged also lends itself to being used in harsher environments, namely mining, food and beverage, plastics, and other industries.

Real-World Impact of G120C VFD

Industrial users have testified to the energy and productivity benefits of system upgrades using SINAMICS G120C drives. The location reduces kWh consumption for pumping, fanning, and mixing by adjusting motor speed to actual load. The drives have energy management features that assist organizations in attaining sustainability goals: these allow machines to idle or stop on their own and yield usable data to the operators.

For example, on a packaging line retrofit, G120C drives on conveyor ships and mixers draw less power during slow-rate production. In water treatment, VFD-controlled pumps are known to reduce power consumption by at least half compared to that of valves running at full speed. In some drive case applications cited by Siemens, energy savings go up to 60%. From this point forward, energy savings during the life span of equipment become the first NRA.

The SINAMICS G120C drive also uplifts uptime and quality beyond energy savings. Its neat control reduces the mechanical stress applied to the motors, thereby extending maintenance intervals. In combination, the integrated safety and diagnostics provide for fewer unplanned stops. Altogether, SINAMICS G120C drives give factories that little edge to run leaner, greener, and with higher ROI on motorized systems

Conclusion

The SINAMICS G120C VFD is a small yet highly capable drive that directly contributes to energy efficiency in an industrial setting. Advanced vector control, flux optimization, and energy tracking assist in lowering production costs; on the other hand, the compact design and safety features lessen the burden on system engineering. Naksh Technology Solutions LLP is a trusted supplier of Siemens automation products; they supply the G120C for the purpose of helping industrialists and OEMs in motor-driven processes, from conveyor belts to HVAC, with better performance and reliability.

FAQs Related to SINAMICS G120C Drive

Q: What is the SINAMICS G120C?

A: The SINAMICS G120C is a compact Siemens VFD for three-phase motors (0.55–132 kW). It offers V/f and vector control, integrated safety (STO), and efficient speed/torque management for pumps, fans, conveyors, and mixers.

Q: How does the G120C save energy?

A: It uses vector control and ECO mode to cut motor losses and power draw. Built-in energy monitoring and PROFIenergy support help reduce idle consumption—saving up to 30% or more in variable-load operations.

Q: What is the difference between G120C and G120?

A: The G120C is a compact, all-in-one drive for single motors up to 132 kW. The modular G120 series supports up to 250 kW and allows greater customization. G120 suits larger systems, while G120C fits OEM and space-limited setups.

Q: What environments is the G120C suitable for?

A: Designed for indoor use (IP20, 0–40°C), it meets EMC and safety standards. With coated electronics, it’s ideal for manufacturing, HVAC, and process automation. For harsh areas, install it in protective enclosures.