Find the right Siemens HMI panel for your industrial automation project in India’s textile mills or high tech pharma plants. We will explore screen size, features, durability and integration which are the key buying criteria for Siemens Basic Panels vs Comfort Panels. For Indian industries like automotive, food processing and renewables, get expert tips from Naksh Technology Solutions LLP to make your project succeed. Ready for optimization of your operations? Let’s dive in!

Overview: Selecting a Siemens HMI Panel in India

- Define Project Scope: Choose screen size and touch type based on task. Small panels for simple monitoring and larger for complex control in factories.

- Basic vs Comfort Panels: Simple applications require basic panels. Comfort Panels deliver advanced graphics and connectivity for tough setups.

- Ensure Compatibility: Verify integration with simatic hmi software WinCC hmi & protocols like PROFINET/PLC connectivity.

- Consider Indian Conditions: For humid or dusty environments – common in India’s industrial hubs – prioritise rugged panels.

- Leverage Local Expertise: Work with approved dealers such as Naksh Technology for tailored solutions & strong support.

Understanding Your Project’s HMI Needs in India

For today’s dynamic industrial landscape from Gujarat textile hubs to Maharashtra automotive plants, a Siemens HMI panel is the nerve center of machine control. This is where operators control conveyor speeds, set mixing ratios in pharma batches or monitor temperatures in food processing lines. Step one to getting it right is knowing what your project demands.

First sketch out your operational needs. In rural setup a single hmi control panel may be sufficient for a small pump station but many panels are required for synchronized control of a large textile dyeing line. Consider the operator’s tasks: Need quick touch inputs for rapid packaging or precise key-based controls for glove-heavy chemical plants?

Power fluctuations are typical of tier-2 cities and so panels require robust power supplies. If you define these upfront, your siemens simatic hmi will respond to your project challenges. Think about scale too. For example, small OEMs in India usually start with compact setups but plan for growth in the longer run.

Not sure which Siemens HMI solution fits your automation needs? Our ultimate guide has the answers.

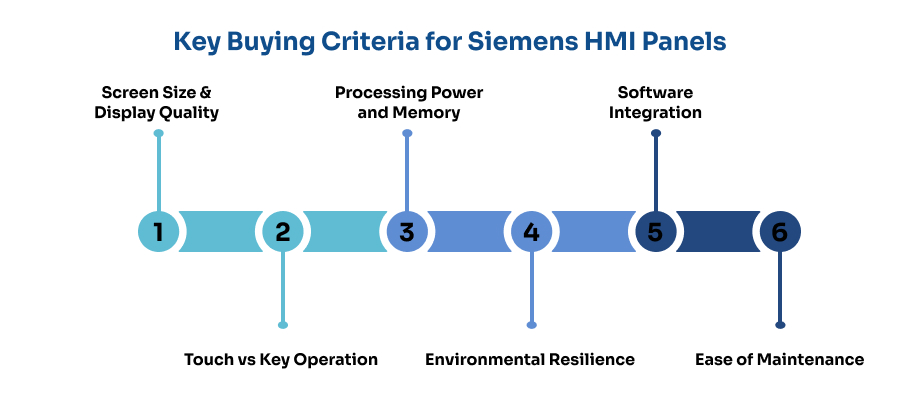

Key Buying Criteria for Siemens HMI Panels

With a Siemens HMI board you choose functionality in balance with project requirements. Focus on these criteria to make a smart choice in India’s competitive automation market where efficiency drives profitability:

- Screen Size & Display Quality: Small 4-7 inches screens fit small control cabinet boxes in machine tools, and 10-22 inch displays fit plant floors that need clear visuals for real time data. High resolution screens up to 64,000 colors for Basic/16M for Comfort make motor speeds or batch errors pop – critical for quality checks in automotive lines.

- Touch vs Key Operation: In quick-moving environments like packaging, where operators adjust settings on the fly, touchscreens speed inputs. Key-based panels also reduce errors in heavy industries such as chemicals where workers use gloves. The two are available in hybrid form for flexibility.

- Processing Power and Memory: For graphics and alarms look for ARM processors with 128 MB RAM. Faster processors cut response times in India’s high output factories so production can continue during peak hours.

- Environmental Resilience: IP65 or higher ratings for dust, water and humidity – essential during monsoons and oily workshops. In conveyor-heavy logistics or textile plants vibration resistance is very important.

- Software Integration: Panels using wincc siemens/TIA Portal facilitate programming. Look for runtime licenses whose tags scale with project complexity (1,001 for Basic 50,000 + for Comfort).

- Ease of Maintenance: Easy to troubleshoot panels with intuitive diagnostics like LED alerts and software logs. In India where downtime can stop export orders, quick fixes are lifesavers.

Siemens Basic Panels: Simple, Reliable Solutions

For startups and small-scale setups, Siemens Basic Panels provide dependable HMI performance without unnecessary complexity. The ARMs are found in India’s cost-conscious plastics/textiles sectors and are energy efficient and can be easily integrated with Siemens PLCs.

- KTP700 Basic Panel: A 7-inch 800×480 touchscreen for single machine monitoring – injection molders/injection. As many as 1,000 tags supported by WinCC HMI basic runtime – alarms, trends and logs covered.

- TP1200 Basic Panel: Its 12-inch widescreen panel is ideal for food processing assembly lines. The larger screen makes visibility better and allows operators to see production data live.

- Energy-Efficient Design: Constructed to draw less power, such panels are especially useful in regions with unsteady grids to reduce operation costs while preserving reliability.

- Simple Integration: Connects easily to Siemens S7-1200PLCs via PROFINET in most small and medium-sized factories in India.

- User-Friendly Operation: Conceived for easy learning, operators can learn functions in hours.

Siemens Comfort Panels: Advanced Control for Complex Projects

In projects that require high speed processing, advanced visuals and complex system integration, Siemens Comfort Panels provide the power and flexibility required. They suit pharmaceuticals, automotive, renewables and other industries moving towards smart manufacturing. Let’s look at some of the Siemens Unified Comfort Panels features:

- TP900 Comfort Panel: A 9 inch 1280×800 multi-touch display with up to 4,000 tags. It supports scripting and user management for multi-shift pharma plants.

- Unified Comfort Panels: Take HMIs beyond with HTML5 dashboards, edge computing & IIoT-ready connectivity. A 15-inch Unified Panel can cut defects by upto 12%.

- Hygienic Stainless-Steel Options: IP69K versions can be cleaned under high pressure – ideal for food and dairy plants requiring high hygiene standards.

- Seamless Legacy Integration: Advanced protocols like Modbus TCP support factories with mixed technologies to integrate older systems without major upgrades.

- Scalable for Growth: From EV battery lines to renewable energy setups, Comfort Panels scale up as operations grow, offering a future-proof solution for Indian industries.

Compare Siemens HMI with other leading HMI solutions to see why it stands out in industrial automation.

Navigating the Indian Market for Siemens HMI Panels

Make in India & Industry 4.0 are driving India’s automation sector to a rapid expansion. Siemens Simatic HMI panels lead the market with a strong dealer network and are constantly evolving with IIoT, energy efficiency and smart factory readiness.

- Adoption of IIoT & Smart Factory: Renewable energy and automotive markets require Unified Comfort Panels. They are digitally ready with HTML5 dashboards & IIoT connectivity.

- Energy-Efficient Panels: New generation Siemens HMIs use 15-20% less power – an advantage in India’s cost-sensitive and energy-intensive manufacturing environments.

- Local Supply Advantage: Dealers such as Naksh Technology deliver from Bangalore, Chennai and Ahmedabad within hours. This reduces lead times which important for export-driven industries.

- Authorized Dealer Benefits: Genuine Siemens panel purchases through authorized dealers includes warranty and technical support.

We Simplify Your Siemens HMI Choice at Naksh Technology

Choosing a right Siemens HMI panel means matching screen size, processing power and connectivity to your project needs, be it a small textile unit or an enormous pharma facility. Siemens Basic Panels vs Comfort Panels for every Indian industry with efficiency, durability & easy integration with simatic hmi software like WinCC hmi. With the right panel you increase productivity and cut errors in demanding environments.

Naksh Technology Solutions LLP is your Ahmedabad partner for Siemens expertise. We’ve powered innovations like India’s first butter paper automation, ISO 9001 certification and global projects in the UAE, Mexico and beyond. Need a bespoke hmi control panel solution? Call or visit https: Contact us to discuss your project & keep your operations running smoothly.

FAQs Related to Siemens HMI:

Q.1. What is Siemens SIMATIC HMI / What types are available?

Ans: Siemens SIMATIC HMI (Human Machine Interface) panels enable operators to monitor and control automation processes. Types include Basic Panels, Comfort Panels, Mobile Panels, Unified Comfort Panels, and Industrial PCs with WinCC Runtime for advanced visualization.

Q.2. What communication protocols do Siemens HMIs support?

Ans: Siemens HMIs support PROFINET, PROFIBUS, Modbus TCP/RTU, Ethernet/IP, OPC UA, Industrial Ethernet, and MPI, ensuring smooth integration with Siemens and third-party automation systems.

Q.3. How to upgrade or update firmware/software of Siemens HMI panels?

Ans. To update Siemens HMI firmware, download the latest version from Siemens Support, then install it via TIA Portal, WinCC, USB, or memory card. Always back up project data before updating.