Still using old PLCs in your automation setup? Discover how the SIMATIC S7 1200 delivers best ROI in manufacturing and textiles. From compact design to seamless integration the S7-1200 PLC increases efficiency, cuts costs and ensures future proof operations. Find out how Siemens PLC S7-1200 stands out and how Naksh Technology Solutions LLP can implement it at your plant.

Overview: Why Choose SIMATIC S7 1200 for PLC Replacement?

The SIMATIC S7 1200 is ideal for replacing outdated PLCs because:

- Compact Design: Fits small spaces. Ideal for machine builders.

- Cost Efficiency: Low energy & maintenance cost.

- Scalability: Adapts to changing automation requirements.

- Seamless Integration: Compatible HMI, SCADA and IoT systems.

- Reliability: Failsafe options assure uptime in critical applications.

Naksh Technology Solutions delivers tailored Siemens PLC S7-1200 solutions for maximum ROI.

The Challenge of Outdated PLCs in Industrial Automation

Industrial automation requires precision, but aging PLCs can suffer performance. Many legacy controllers lack modern connectivity, draw excessive current and require frequent maintenance. For textiles or food processing this means downtime, higher costs and missed opportunities for optimization. The s7 1200 plc solves these problems. The compact size, advanced features and low-cost operation make it an ideal replacement for old PLCs for plant competitiveness.

Common Issues with Legacy PLCs

- Limited Connectivity: The older PCs have trouble with IoT or cloud integration.

- High Energy Use: Inefficient operation raises power bills.

- Frequent Downtime: Aging hardware causes expensive repairs.

- Lack of Scalability: Cannot cope with modern automation demands.

- Solution: For these pain points the S7-1200 PLC offers modern features.

What Is the SIMATIC S7 1200?

The s7 1200 plc is a compact medium-sized PLC from Siemens. It combines powerful processing, integrated communication (PROFINET, Modbus) and technology functions like motion control. In standard and failsafe versions the Siemens PLC S7-1200 is flexible and reliable for textiles, packaging and HVAC. And unlike older PLCs, the S7-1200 PLC supports modern protocols enabling smart factories. Its small footprint fits in tight spaces and its TIA Portal software makes programming easy.

Learn how Siemens S7-1200 PLC simplifies compact automation with advanced features and seamless integration.

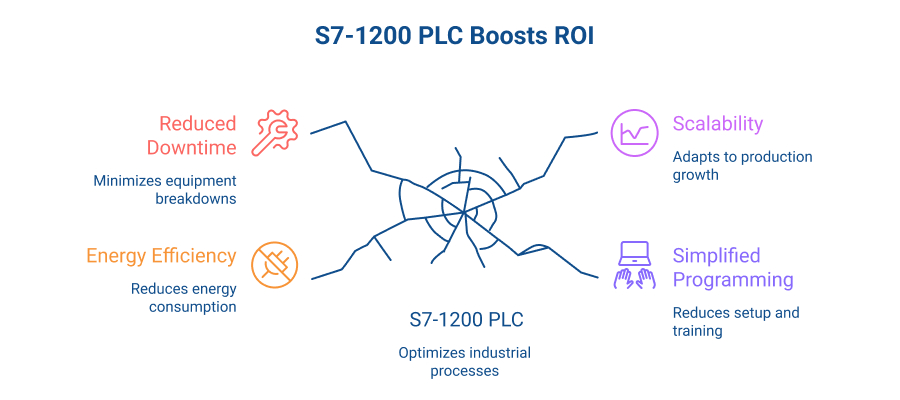

How SIMATIC S7 1200 Boosts ROI

The SIMATIC S7-1200 addresses key industrial challenges to increase ROI. Here’s how it delivers value:

- Energy Efficiency: Earlier PLCs waste energy running inefficiently. The S7-1200 PLC optimizes energy use up to 20% less consumption, Siemens data show. For a 24/7 textile plant this translates to big savings.

- Reduced Downtime: With rugged hardware and failsafe options, the Siemens PLC S7-1200 reduces breakdowns. Its diagnostic tools spot problems before they become expensive stoppages. Packaging plant downtime was reduced by 15% with Naksh Technology’s S7-1200 PLC implementation.

- Scalability for Growth: You can add I/O modules or communication interfaces to the s7 1200 plc through its modular design. This flexibility means your investment lasts – whether you upgrade a single machine or a whole production line.

- Simplified Programming: TIA Portal integrates programming, visualization & diagnostics to reduce setup time. Operators can configure the Siemens PLC S7-1200 fast, without training costs.

Key Features of SIMATIC S7 1200 for Industrial Automation

Why is the siemens plc s7 1200 unique? Features are adapted to modern automation:

- Compact Size: Tight fit in tight control cabinets – great for machine builders.

- Integrated PROFINET: Connects to HMIs, drives and IoT platforms.

- Failsafe Options: Assure safety in critical applications like chemical processing.

- Motion Control: Supports exact tasks like conveyor positioning in packaging.

- High Performance: Simple logic handling for small to medium size systems.

SIMATIC S7 1200 Models for Different Needs

Different applications require different Siemens PLC S7-1200 models. Here’s a breakdown:

CPU 1211C

- Processing Power: Up to 50 KB of program memory.

- Key Features: Designed for small and low cost applications with basic I/O and PROFINET.

- Best For: Small machines/standalone tasks like HVAC control.

CPU 1214C

- Processing Power: Up to 100 KB of program memory.

- Key Features: More I/O point support, more logic support, more integration with SCADA.

- Best For: Medium-sized systems like textile spinning lines.

CPU 1215C

- Processing Power: Up to 125 KB of program memory.

- Key Features: 2x PROFINET ports, advanced motion control & IoT ready.

- Best For: Those larger setups that need connectivity, like food processing plants.

Failsafe Models (1214FC/1215FC)

- Processing Power: Like standard models but with safety functions.

- Key Features: For safety-critical applications SIL 3-rated.

- Best For: Plants for chemical or pharmaceutical use that require failsafe operation..

Every S7-1200 PLC model mentioned above offers flexibility to replace legacy systems with minimum downtime.

Why SIMATIC S7 1200 Outshines Competitors

The industry-specific siemens plc s7 1200 is a standout in automation because of its numerous advantages:

Seamless Integration: Unlike other PLCs the Siemens PLC S7-1200 is PROFINET compatible with Siemens HMIs, drives and SCADA systems. This makes for unified setup reducing wiring & configuration time.

Future-Proof Design: Support for OPC UA and IoT protocols makes the S7-1200 PLC compatible with Industry 4.0 solutions.

Global Support: Siemens worldwide network with partners like Naksh Technology supports your needs.

Cost-Effective Operation: In contrast with competitors like Rockwell or Mitsubishi, the Siemens PLC S7-1200 balances upfront costs with long-term savings.

How to Replace Your PLC with SIMATIC S7 1200

Upgrading to the siemens plc s7 1200? Follow these steps:

- Assess Current Systems: Identify legacy PLC limitations/automation requirements.

- Choose the Right Model: Choose a S7-1200 PLC such as the CPU 1214C for medium tasks or 1215FC for safety critical applications.

- Plan Integration: Check compatibility with existing HMIs/SCADA via PROFINET.

- Partner with Experts: Work with Naksh Technology for installation & training.

Naksh Technology: Your Partner for SIMATIC S7 1200 Success

The SIMATIC S7 1200 offers the highest ROI on PLC replacement with energy savings, scalability and easy integration in textiles & food processing industries. Its compact design, PROFINET connectivity and failsafe options make the S7-1200 PLC an ideal solution for modern automation – cutting costs and increasing efficiency. Need to upgrade your plant? Call Naksh Technology Solutions LLP and get your SIMATIC S7 1200 today.

FAQs Related to SIMATIC S7 1200:

Q.1. What TIA Portal license do I need to program S7-1200, and to simulate it?

Ans. Programming: STEP 7 Basic is sufficient for S7-1200; use STEP 7 Professional if you also work with S7-300/400/1500. Simulation: PLCSIM is included, but S7-1200 G2 simulation may prompt for additional licensing (e.g., PLCSIM Advanced or Pro) depending on setup/version.

Q.2. Does S7-1200 support both PROFINET and Modbus TCP (at the same time)?

Ans. Yes. S7-1200 communicates over PROFINET and has built-in MB_CLIENT/MB_SERVER blocks for Modbus TCP via the onboard Ethernet port; both can be used concurrently (subject to connection resources).

Q.3. Are safety (failsafe) versions available, and do I need extra licenses?

Ans. Yes, S7-1200F CPUs support Safety Integrated (Profisafe to safety I/O/drives). As of TIA V20, base engineering for S7-1200F/G2 is included (no separate “Safety Basic” license), while enabling/using F-functions follows the Safety manuals/guidelines.