The Siemens servo motor (SIMOTICS) and servo drive Siemens (SINAMICS) provide the best performance in the industry for precision motion control. For instance, Siemens claims that SIMOTICS S synchronous servomotors provide “accuracy, robustness, and a wide range of designs” and that they are “the first choice for highly dynamic and exact motion paths.” Such high-performance motors, when combined with the SINAMICS servo drives (including the V90), offer complete motion control solutions. The SINAMICS V90, a widely used single-axis drive, is described by Siemens as a “performance-optimized and easy-to-operate” solution covering 0.05–7.0 kW in both single- and three-phase networks. This guide explains the working principle of these components, the qualities that set Siemens servo technology apart, and their application in industrial automation systems.

What Is a Siemens Servo Motor?

A standard small-sized Siemens servo motor (Tower Pro SG90) employs the same principle of feedback as industrial servos do. Any servo motor is basically an electric motor equipped with a built-in position feedback unit.

Hence, it adjusts its movement continuously in a closed-loop operation system so as to obtain the actual value of the commanded angle or speed. As far as supplies from Schneider Electric are concerned, servos are used in a closed-loop mechanism which registers its position feedback to control its rotational speed. In real-world applications, the position of the motor is detected via an encoder or its equivalent of a position transducer type called resolver, and then its electronics make a continuous comparison between actual position and command, so that any corrections of even slight errors can be done on-the-fly. One organization within the industry describes this device as a small, self-contained electrical device which precisely moves and rotates parts. A result of that is exact motion: Servo motors accelerate fast to a certain set speed or position and keep it there with very few errors, hence the importance of the applications in robotics, CNC machines, conveyors, and automation equipment.

Discover how our advanced Siemens Servo Motor for High-Performance Textile Machinery can enhance speed, precision, and energy efficiency in your textile production lines.

SIMOTICS S Series Siemens Servo Motor

Siemens names its servo motors under the SIMOTICS brand. The SIMOTICS S series is a brushed synchronous servomotor family built for highest precision and dynamic responsiveness. According to Siemens, SIMOTICS S motors are known for “accuracy, robustness, and a wide variety of constructions” and are considered “the first choice for highly dynamic and exact motion paths”. In other words, SIMOTICS S motors excel in very fast accelerations and high speeds to provide consistent performance even under load.

For instance, the SIMOTICS S-1FK7 series is a set of permanent-magnet synchronous motors that come in Compact, High-Dynamic, and High-Inertia versions. Siemens described these 1FK7 motors as being “characterized by superior overload capability, ruggedness and compactness”, meaning these machines can withstand short bouts of heavy loading (overload) without damage, and their sturdy design stands up well to being used in the workshop. In combination with these motors are rotatable connectors and preassembled cables for rapid installation. Practically speaking, a SIMOTICS S-1FK7 can very rapidly spin up an extremely heavy machine part while maintaining tight control.

In every divisible range of frame sizes, SIMOTICS S motors have many options (the one shown above 1FK7 is about midway in frame size; 1FL2, 1FL6, and so on, are used for smaller or bigger power requirements). A Siemens servo drive is paired to the SIMOTICS S motor in a complete system. For example, Siemens mentions the coupling of the SIMOTICS S-1FL6 motor with the SINAMICS V90 drive for a power rating of 0.05-7.0 kW in both single- and three-phase networks. This modular combination ensures that the drive is selected in accordance with the rated power of the motor. In this way, the SIMOTICS S family serves as a fully equipped, versatile, and high-quality servo platform for the engineer, ranging from simple positioning tasks to elaborate, high-speed motion.

Siemens Servo Drives: SINAMICS Series

SINAMICS family includes the drives of servo type from Siemens and caters to different needs. The SINAMICS V90 is a well-known single-axis servo drive. It is specifically meant for simple motion control tasks. According to Siemens, the “SINAMICS V90 servo drive system” is “performance-optimized and easy to operate.” The V90 can deliver power from 0.05 to 7.0 kW (0.07 to 10 HP) running either on 230 V or 400 V supplies. Among others, it integrates safety functions, and it supports common industrial protocols for ease of integration into PLC (PROFINET, USS, Modbus RTU).

V90 drive works most often in conjunction with a SIMOTICS S servomotor, such as the S-1FL6 or S-1FK7, to form a compact servo system. For more sophisticated applications, Siemens provides multi-axis modular drives (e.g., the SINAMICS S120 or S210 lines) that can coordinate multiple motors or higher power; meanwhile, the V90 remains the preferred solution for intermediate-level motion applications.

Initially, it is explained that a servo drive practically acts as both an amplifier and a controller. That is to say that motion commands (target position, speed, or torque) sent from an upper-level controller or PLC are received by the drive, which then feeds the motor with the exact current needed to follow that command. According to Schneider Electric, a servo drive “can also be termed as an amplifier due to its ability to take the control signals … and escalate [them] to give out a certain amount of voltage and current to the motor”.

The drive basically “tells the Siemens servo motor what to do and how to do it at lightning speed”. The drive continuously watches feedback (from the motor encoder), constantly changing its output, creating a closed control loop. This results in fast and accurate motion for the system. According to them, “the servo drive offers a wide range of advantages, such as superior positioning, greater speed, and efficient motion control”, which is why it finds use in the high-speed and high-precision automation arena.

What are the major differences between Siemens Servo Motor and Servo Drive Siemens?

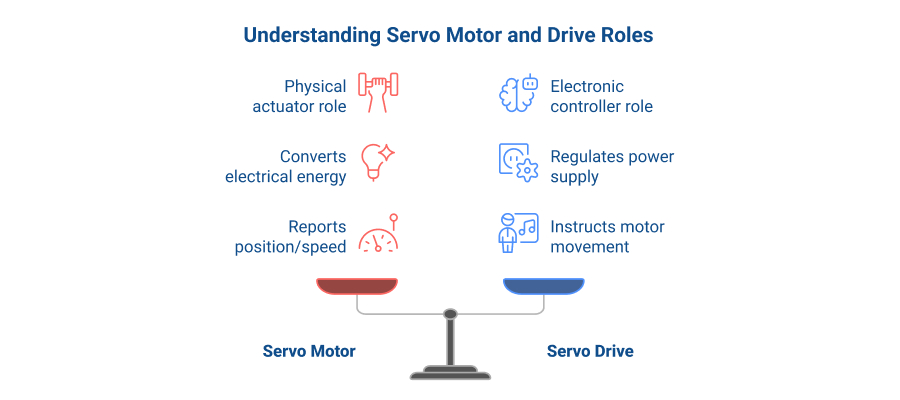

Customers often want to know the difference between a servo motor and a servo drive. Here is the simplest explanation: the servo motor is the physical actuator (the “muscle”), while the servo drive is the electronic controller (the “brain”). Therefore, the servo motor converts electrical energy into motion: It contains windings, magnets, a shaft, and a feedback encoder. With no drives, the servo motor will just spin around like a standard motor without any control. Conversely, a servo drive is simply an electronic box without any shaft to turn.

Depending on the command inputs, the servo drive will feed the motor with regulated power; it calculates the trajectory and feeds the motor with the voltage/current needed to perform the movement. As ESI Motion explains, the drive instructs the Siemens servo motor on what to do and how to carry it out-with-speed. On the other hand, the servo motor reports position/speed back to the drive through an internal sensor.

As already stated by Schneider Electric, a “servo uses position feedback to control rotational speed” in a closed loop. This practically means that the drive and motor keep a continuous conversation between themselves; the controller, through the drive, sets a target, the motor moves to do so, reports back on the execution, and the drive quickly accommodates any further correction required.

To summarize: the servo drive is an amplifier/power unit that has motion-control algorithms, and a Siemens servo motor is the rotary actuator with feedback. The drive feeds the motor, and the motor feeds back to the drive concerning its status. Together they complete the closed-loop system that can accurately control position, speed, and torque.

Learn how Siemens Drives for Energy-Efficient HVAC and Chiller Plants help reduce operational costs while maintaining optimal climate control.

Applications in Industrial Automation

Siemens servo motor and drives enjoy ubiquitous popularity in modern industrial automation. Precise speed and position control render a solid choice for any applications that involve repeatable motion. Typical applications include CNC machine tools, laser cutters, and spindles; robotic arms and pick-and-place robots; packaging and converting machines; automated assembly lines; printing presses; and high-speed conveyors. Schneider Electric identifies servo applications as being in “machine tools, packaging, factory automation, material handling, printing, assembly lines, CNC machinery, [and] robotics applications.” Practically speaking, this means that servo drives consistently position machines and robots were programmed in every cycle, sometimes thousands of cycles each hour.

The advantage of servos in these applications lies in accuracy and dynamics. Being closed loop, any deviation is immediately detected and corrected. A Kollmorgen document further states that servo systems provide “the greatest possible positional accuracy, speed control and dynamic response”.

They are torquing dense, high torque at low speeds, requirements for indexing large loads, sudden changes in motion directions. Of course, with these qualities there are a greater level of complexity and price, but these are the merits that cannot be compromised in factories or automation installations. For instance, a high-speed packaging machine can position bottles on a conveyor with sub-millimeter precision at hundreds of picks per minute, using a Siemens servo drive and motor.

In summary, in all these applications for motion control, from automotive assembly to precision printing, SIMOTICS servo motors and SINAMICS drives constitute the fundamental back end of the motion system. They may handle everything from delicate position control, like a robotic welder, to ferocious torque demands of a heavy-duty forming press, all the while keeping in synchronization and speed.

The Conclusion: Get Partnered with Naksh Technology Solutions LLP

Siemens servo systems are the state-of-the-art version for industrial motion control (SIMOTICS motors and SINAMICS drives). The synergy of precision, power, and ruggedness serves factories worldwide where efficiency and performance are of value. For engineers and purchasing teams, the crucial step of deployment rests in having a reliable distributor.

Naksh Technology Solutions LLP is one of the most credible suppliers and engineering solutions of Siemens motion-control products in the country. With Naksh, you receive genuine Siemens servo motor and SINAMICS drives-with the backing of the Siemens warranty and expert support. Be it a single 0.4 kW SIMOTICS S-1FL6 motor or a 200 axis SINAMICS turnkey system, Naksh can provide you with the appropriate products and support.

You can confidently choose Naksh Technology Solutions LLP for sourcing Siemens servo motor and servo drives-the precision and reliability your automation project demands.

FAQs:

Q: How do I source genuine Siemens servo products?

A: To ensure quality and support, Siemens servo motors and drives should be purchased through authorized suppliers. Naksh Technology Solutions LLP is a Siemens-trusted partner and distributor, offering the full range of SIMOTICS servo motors, SINAMICS V90 drives (and related controllers), and other Siemens motion-control components. Naksh provides technical consultation, system design assistance, and post-sales service to help procurement teams and engineers select the right components for their automation projects.

Q: What is the difference between a servo motor and a servo drive?

A: A servo motor is the actuator that produces motion, while a servo drive is the controller that powers and regulates that motor. The drive interprets motion commands and supplies current to the motor, effectively telling it how fast or far to move. As ESI Motion notes, the drive “tells the servo motor what to do and how to do it at lightning speed”. The motor, in turn, provides feedback to close the loop (as a Schneider guide explains, servos “register position feedback to control… speed”). In short, the motor is the mechanical device, and the drive is the electronic brain that drives it.

Q: What are common applications for Siemens servo motors and drives?

A: Siemens servos are used in virtually all advanced automation applications. Examples include CNC machines, robotic gantries, pick-and-place machines, packaging and labeling lines, machine tools, printing presses, automated guided vehicles, and more. In any system where you need tight position or speed control (for instance, moving an encoder wheel to an exact angle or following a precise motion profile), a servo system is likely employed. Siemens SIMOTICS and SINAMICS products are often specified by OEMs and integrators for these tasks due to their proven performance.