Introduction of Siemens HMI

The Human-Machine Interface (HMI) is the user interface or dashboard that connects an operator to a machine or process. Thus, in industrial settings, the HMI provides engineers and plant staff with the ability to monitor equipment, see data trends, and control machinery through touchscreen devices or control panels. Siemens, a global automation leader, carries a complete series of HMIs under the brand name SIMATIC HMI.

Siemens HMI panels are equipped with screens that are said to be clear and interactive to the operators – ranging from simple key button units to multi-touch displays widely used in industries for smart factories and Industry 4.0 solutions. With an intuitive design and reliable performance, the Siemens HMI units allow Indian manufacturers and utilities to gain better control and supervision. One could use the image [Insert Image: engineer interacting with a SIMATIC HMI touchscreen on a production floor] to demonstrate how operators interact with the system.

The guide will explore the SIMATIC HMI series, its features, benefits, applications to various industries (focusing on India), and the selection process for the right HMI.

Overview of Siemens SIMATIC HMI Series

The company offers many series of SIMATIC HMI panels designed to be adapted to varying needs. The key series include:

-

Basic Panels of SIMATIC HMI:

This family consists of first-level HMIs for simple applications. These second-generation panels come in 4, 7, 9, and 12″ touch or combined key-touch displays. Their presentation is on a widescreen with high resolution (64K colors), and they are energy efficient.

-

SIMATIC HMI Comfort Panels:

Touch panels for highly advanced visualization. Comfort Panels (usually 7″ to 15″ and more) offer powerful processing capabilities, multiple communication ports, and ruggedized variants (either IP65 or stainless steel). They serve as the upper foundation for specialized versions like the one with IP65 protection or washdown.

-

SIMATIC HMI Key Panels:

Small-size operation panels with manual keys and indication of processes. Key Panels are in an application where the touch screen is not needed; therefore, simple pushbutton controls with or without tiny displays are used.

-

SIMATIC HMI Mobile Panels:

Portable, handheld touch panels for mobile machine control. They facilitate operators carrying an HMI around the plant for diagnosis or calibration.

-

SIMATIC HMI Unified Panels:

Newest-series HMIs, circa 2025, featuring modern technologies. Unified Basic Panels (4″–12″) are small and cost-friendly, whereas Unified Comfort Panels (7″–22″) can be used in multi-touch mode with additional communication options that include an IP65 rating for hygienic applications. All Unified Panels are running SIMATIC WinCC Unified software and are even providing integrated remote access for new operating concepts.

-

SIMATIC HMI Multi Panels and Industrial PCs:

Large-screen operator stations and panel-PCs for SCADA-level applications. They run PC-based WinCC software-level control software for complex, distributed control systems.

Every SIMATIC HMI family is designed to work smoothly integrated with the Siemens TIA (Totally Integrated Automation) ecosystem. All models support the same programming environment, SIMATIC WinCC, so that they are easily configurable across multiple panel sizes. In practice, this means that engineers can scale from a 4″ Basic Panel all the way up to a 22″ Comfort Panel or PC-based system, recycling screens and logic.

Also Learn, How Siemens HMI is Used in Airport Baggage Handling Systems

Siemens HMI Models We Offer

| SIMATIC HMI Series | Popular Models |

| Basic Panels | KTP400 Basic, KTP700 Basic PN, KTP700 Basic DP, KTP900 Basic, KTP1200 Basic PN, KTP1200 Basic DP, KP300 Basic Mono PN, KP400 Basic Color PN |

| Comfort Panels | KTP400 Comfort, KP400 Comfort, TP700 Comfort, KP700 Comfort, TP900 Comfort, KP900 Comfort, TP1200 Comfort, KP1200 Comfort, TP1500 Comfort, KP1500 Comfort, TP1900 Comfort, TP2200 Comfort |

| Unified Comfort Panels | MTP700 Unified Comfort, MTP700 Unified Comfort Neutral, MTP1000 Unified Comfort, MTP1000 Unified Comfort Neutral, MTP1200 Unified Comfort, MTP1200 Unified Comfort Neutral, MTP1500 Unified Comfort, MTP1500 Unified Comfort Neutral, MTP1900 Unified Comfort, MTP1900 Unified Comfort Neutral, MTP2200 Unified Comfort, MTP2200 Unified Comfort Neutral |

| Unified Basic Panels | MTP400 Unified Basic, MTP700 Unified Basic, MTP1000 Unified Basic, MTP1200 Unified Basic |

Key Features of Siemens HMI

SIMATIC HMI panels feature advanced hardware and software:

- Display: A Siemens HMI uses an ultra-bright TFT screen with 16 million colors for the greatest graphic effect. The display is rated for an 80,000-hour minimum, with a backlight and wide (170°) viewing angles. A lot of display models come with a widescreen 16:9 format, which gives up to 40% extra visualization area as compared to the conventional 4:3 screens. Some of the most vivid displays ensure alarm messages and data are clearly readable in the control room.

- Connectivity and Networking: This HMI comes with inbuilt drivers for usual industrial networks. Basic models come with PROFINET/Ethernet interfaces, often with 2-port switches to daisy-chain panels. It also supports PROFIBUS and Modbus over TCP/IPassets.new.siemens.com. One may find multiple Ethernet ports (10/100/1000 Mbps) and USB slots for printers, barcode scanners, or data backups in many units. This can thus facilitate HMIs’ direct connection to Siemens PLCs (S7-1500, S7-1200, etc.) and even third-party controllers (Allen-Bradley, Mitsubishi, Omron, Modicon, OPC UA).

- Rugged Industrial Design: SIMATIC HMIs are made for tough factory atmospheres. Many panels have rugged aluminum casings and conform to vibration and chemical resistance standards. Comfort and Unified panels are given in the premium variants with dust and water resistance designations of IP65 or IP66k.new.siemens.com. The new Unified Comfort Panels even allow full glove operation and have smart touch cancelation to avoid undesired inputs. These HMIs, hence, can withstand heat, dust, moisture, and heavy usage in Indian plants.

- User-Friendly Interface: Siemens HMI software charts drag and drop graphics to intuitively drag and multitouch operate on touchscreen models, making the navigation as intuitive as a smartphone. The user interface supports more than one language, text fonts, and alarm/recipe management. Known WinCC tools enable engineers to quickly create custom screens with charts, trends, buttons, and faceplates.

Read our blog on, Siemens HMI vs. Other HMI Solutions: Why Choose Siemens?

- Web and Remote Access: Many SIMATIC HMI systems are provided with an embedded web server. Operators can remotely view and control HMI screens via Ethernet (from, say, a tablet or a PC) without the installation of additional software. The recently released Unified Panels come with two built-in web clients for remote operation. To add some spice to the security features, the panels run on SIMATIC Industrial OS with interfaces and firewall settings that can be configured.

- Data Backup & Replacement: The driving feature of Siemens HMIs is the automatic backup of the system image onto the SD card. In the event of replacement, the user just must insert the SD card into the new panel, and all configurations and graphics get restored immediately. This ensures that downtime during replacement is kept to a minimum. Alongside this is the “Pack and Go” functionality that allows an engineer to send configuration changes to panels without having to connect to a PC.

- Scalable Software Platform: All panels of SIMATIC HMI undergo configuration using SIMATIC WinCC software (Portal or Unified editions). A single WinCC project can be used for any panel size and accordingly scales the graphics automatically. Using one piece of software, therefore, greatly reduces the amount of engineering work required when one needs to upgrade, say, from a small Basic Panel to a much larger Comfort Panel or PC-based system.

These key features make Siemens HMI panels a powerful and flexible choice for modern automation systems.

Top Benefits of Siemens HMI for Industrial Automation

There are several benefits to be realized from the application of Siemens SIMATIC HMI to an industrial automation setting:

- Enhanced Productivity: Real-time visualization means operators can promptly obtain machine data, KPIs, and alarms. Crisp and clear HMI screens enable less time in choosing wrong decisions or in the delay in responding to faults. By removing the guesswork, Siemens HMI provides plant personnel with powerful tools to circumvent any blocking issue until its downtime, leading to increased production efficiency.

- Improved Efficiency and Quality: The HMI’s design-to-user interface reduces training costs and eliminates mistakes by operators. Technicians have the points they need to monitor the process, adjust setpoints, and enter parameters on the fly using basic touchscreen technology. This simple, yet powerful control flow reduces unnecessary manual intervention while maximizing smooth running of production.

- System Integration without a Hitch: Siemens HMIs in the Totally Integrated Automation (TIA) portfolio provide a native interconnection with SIMATIC PLCs, SCADA, drives as well as other hardware used in automation. Data smoothly flows from one device to another for coordinated control. For example, the SIMATIC HMI TP1200 panel may talk directly to the S7-1500 PLC over PROFINET to synchronize machine status and commands. Being tightly integrated, the line is optimized for performance.

- Scalable to Grow: The range of SIMATIC HMIs caters to a small mass of applications. You can start with a 4″ small panel in your plant and later switch to a 15″ or bigger unit as soon as the need arises. Screens and configurations may then be reused since they all share a common software environment, which is future proof for your engineering investment. Such scalability permits expansion in a very flexible manner without resubmitting an entire control system.

- Reliability and Uptime: Siemens industrial panels have a reputation for durability. Quality hardware and backup features ensure that maintenance is kept at a minimum. Even in rigorous conditions, panels operate steadfastly (IP65 rating stands as the protection against dust and water ingress). If a unit fails, then the SD-card restore and panel replacement features ensure that the systems are swiftly awash upriver, thus lessening the loss in production.

- Lower Total Cost of Ownership: With built-in communication drivers (PROFINET, EtherNet/IP, Modbus, etc.), protocol modules are no longer needed. One programming tool (WinCC) programs all panels, thereby reducing engineering efforts and software licensing costs. Standardizing Siemens HMIs for the long term with worldwide support networks reduces operational costs.

In other words, the Siemens HMI improves machine control by providing a real-time interface that is user-friendly and thus permits operators to be more efficient and maximize plant output. Its reliability and integration make it a good buy for any automated plant.

know more about, Human Machine Interface Siemens: Improving Operational Productivity

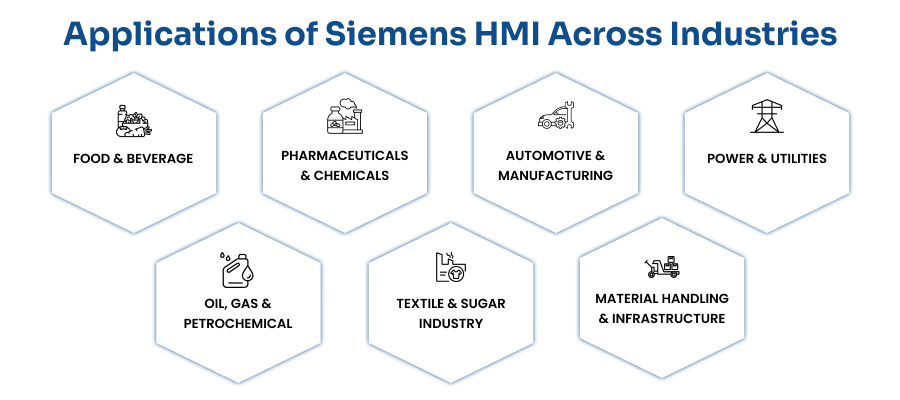

Applications of Siemens HMI Across Industries

Siemens HMI panels find application in diverse industrial fields in India and worldwide. HMI panels find huge demand in the fast-growing industrial sectors of India.

-

Automotive & Manufacturing:

They are used in car assembly lines, CNC machine tools, robot cells, and packaging machines. Hence, operators can use HMI screens to start and stop belts and injection molding machines to meet their production targets.

-

Pharmaceuticals & Chemicals:

In process plants for reactors, mixers, tablet machines, etc. Wash-down IP65-rated HMIs with alarm and recipe features improve product quality.

-

Food & Beverage:

The touch panels watch over bottling lines, food mixers, and packaging. Hygienic panels and glove-worthy touchscreens all conform to sanitary requirements.

-

Power & Utilities:

Installation is carried out in thermal and hydro-power stations, water/wastewater treatment plants, and substation control rooms. HMIs provide central dashboards for distributed I/O and SCADA systems and are often linked to higher-level monitoring software.

-

Oil, Gas & Petrochemical:

Rugged HMIs control pumps, compressors, emergency shutdowns, and other applications in refineries and pipelines. The ability to interface with DCS networks (PROFINET/OPC UA) is, thus, critical in these fields.

-

Material Handling & Infrastructure:

Installed cranes, elevators, conveyors, and building automation systems. The mobile panels help technicians move around large plants.

-

Textile & Sugar Industry:

Widely used for loom controls, dyeing machines, sugar centrifuges, and boilers, thus aiding traditional Indian industries in the modernization of their operations.

Across all these industries, SIMATIC HMI provides a common platform. Its flexibility indicates that one control interface may control a small machine, or it may be scaled up to a control room display. For example, engineers at a packaging plant in Pune may operate a 7″ Comfort Panel on individual machines and a 15″ multi-touch panel for line-level supervision.

When Indian companies insisted on standardizing on Siemens HMI, they enjoyed local support and training. Authorized suppliers like Naksh Technology Solutions LLP, Ahmedabad, stock Siemens HMI panels, plus some integration assistance. SIMATIC HMIs can be customized as per any application, be it a beverage bottling line in Gujarat or a paper mill in Tamil Nadu.

Tips for Choosing the Right HMI

Choosing your HMI should weigh application requirements versus the strengths of the panel. Some key tips include:

- Identify Your Application Needs: Identify what operators will see and do on the HMI. How many I/O signals will be displayed? Does it require complex graphics, animations, or just text? That will define its screen size and resolution. (For instance, Basic Panels 4″–12″ are good for simple machine control, while Comfort Panels 15″ manage complex SCADA views)

- Evaluate Environment and Mounting: Keep an eye on those ambient conditions. If the HMI has to contend with dust and moisture or direct sunlight in its working environment, consider IP-suited models or high-contrast displays. One could go with IP66k hygienic ones for cleanroom or washdown environments. Finally, figure out whether you’re looking at panel-mounting, wall-mounting, or rack-mounting.

- Communications Compatibility: Ensure the panel interfaces match those of your controllers/networks. SIMATIC HMIs support PROFINET/Ethernet by default. In case you have older PLCs, which use PROFIBUS and Modbus, for instance, check if those are built in. For Siemens HMIs, most protocols come supported out of the box. From there, make sure the panel has a sufficient number of Ethernet ports and USB interfaces, should you want to connect cameras or scanners.

- User Interface Style: Choose between touch vs. physical buttons. Touchscreen panels offer more flexibility and a modern design, but if operators wear heavy gloves, make sure the screen is glove sensitive. Alternatively, Key Panels with buttons are reliable for basic start/stop controls. Also consider multilingual support if necessary.

- Software and Licensing: Siemens HMI panels use SIMATIC WinCC (TIA Portal or WinCC Unified) and it is important to check that the engineering team has access to the corresponding software version. (Latest Unified Panels require WinCC Unified.) Having a single software package for all HMI and PLC program engineering greatly contributes to time and cost savings.

- Future Expansion: For future considerations: Plan for growth. It might be wise to choose a slightly larger panel or one with some extra memory if you plan to extend the machine functions later. SIMATIC HMIs are scalable – you can easily migrate your HMI project to a bigger panel of the same family.

- Consult Experts: If you still feel unsure, consult a Siemens HMI expert. Authorized distributors can guide you in panel selection. For instance, contact us via the [Contact Us] page to receive customized guidance on choosing the perfect SIMATIC HMI for your plant requirements.

By choosing the HMI with the right features (panel size, IP rating, connectivity, UI style) to suit your application, you are looking for increased productivity and high-level reliability. Authorized solution partners guarantee you get original Siemens hardware and support.

Conclusion

SIMATIC HMI panels allow an ideal amount of visualization and control for industrial automation. Famous for their highly user-friendly rates, powerful connectivity, and robust design, they are equally available for the testing demands of Indian industries. These panels serve as prime factors for operational efficiency, safety, and flexibility implementations in different application areas. Naksh Technology Solutions LLP provides dependable access to the full range of Siemens HMI solutions, customized to the needs of various industries.

FAQs:

Q: Can Siemens HMI panels work with non-Siemens PLCs?

A: Yes, Siemens HMIs support popular protocols like Modbus, EtherNet/IP, and OPC UA. They can easily connect to controllers from Allen-Bradley, Omron, Mitsubishi, and more—no extra hardware or costs needed.

Q: Are Siemens HMI panels durable enough for tough Indian factory conditions?

A: Absolutely. Siemens HMIs are rugged, with IP65/IP66 protection against dust, water, and vibration. Many models even work with gloves, ideal for Indian industries like pharma, food, and heavy manufacturing.

Q: Is remote access or mobile monitoring possible with Siemens HMI?

A: Definitely. Many Siemens HMIs have built-in web servers, so you can access screens and alarms remotely via PC or tablet. Unified Panels even support multiple remote users at once, great for monitoring from anywhere.